This weekend marks the time when the Skaerbaek Fan Weekend is normally held in Denmark. The event was cancelled due to COVID-19, but the LEGO House® still decided to participate. In previous years they have closed the House to the public and opened it to Skaerbaek Fan Weekend attendees only. This year they held a virtual event with a few presentations from various employees. To mix things up, most of the employees presenting were not designers so it was interesting to hear about different parts of the company. Here’s a quick run through of the event with a few screen shots I took.

Quick admin… there were about 400 people logged in from across the world. I saw people check in from North America, Europe, Asia, and Australia. It occurred between 1PM and 5PM in my local time zone (Central European Time) so great for me and a good excuse to take a day off from work. Sorry for those of you who had to get up early or stay up late. Participants were in receive only mode. You could type questions into chat and Jan Beyer moderated and picked the questions for the presenters to answer.

DISCLAIMER: These are from the notes I took during the session. I may have made mistakes or heard things wrong. So don’t go quoting me on anything without confirmation from the LEGO Group.

To start off, there was a welcome by the Managing Director of LEGO House, Jesper Vilstrup.

Jesper gave a quick welcome and updated us on the LEGO House® and impacts due to COVID-19. It was closed for about 100 days until it re-opened at reduced capacity. They have re-opened with a bunch of new rules and increased hand washing. Also, they swap out all of the bricks every day and put them in a 72 hour quarantine. I can’t imagine how long that takes.

Next up was Julia Goldin (calling in from London). She is the Chief Marketing Officer and Executive Vice President of the LEGO Group. She is pictured on the right in the screen shot below.

She gave an overview of what she does and talked about a few items before Q&A. The intro items were:

-LEGO is expanding offerings to adult fans and plans to continue the expansion

-70 or so projects in the portfolio geared towards adults (IDEAS and others)

-LEGO wants feedback from the fan community

-A quick overview of her personal use of LEGO

-A quick discussion on sustainability of LEGO to include removal of the plastic parts bags in 2021

-A focus on digital child safety

-A discussion on Diversity and Inclusion within the LEGO Company

Fan Q&A

-Will Bionicle return?

—It was phased out as it was not seen as part of the kid building experience, but it could return someday

-Any updates on the BrickLink acquisition?

—BrickLInk is getting new customers during COVID, adult fans are important to LEGO and she sees BrickLink as a way to support adults, using BrickLink to learn more (data mining?), LEGO does not want to change Bricklink

-Talk about the partnerships with Ikea, Levis, and Adidas

—Wanted an opportunity to show LEGO in a different way when two brands combine in new channels, looking for ways to expand brand awareness, don’t expect a lot of new partnerships beyond what has been seen, Ikea partnership was done as LEGO saw a need for buildable storage (not everyone has a giant room to store their massive collections)

-LEGO is open to releasing older themes

-LEGO is looking into releasing smaller sets geared towards adults at lower price points

-A quick discussion on the COVID-19 impacts

Next up was Poul Schou. Poul is the Senior Vice President for product development in the LEGO Group and has been with the company for over 30 years.

Poul provided a quick history of his employment at LEGO to include traveling the world bringing LEGO to places that had never seen LEGO (to include a great story about bringing bricks to Papua New Guinea). He was involved in bringing LEGO to China in early 2000. He then worked in Denmark on marketing for a short period before switching to product development. He now has a team producing ~200- new products per year and he called them Product Group 1. They make products for younger kids (4+/Juniors), girls lines (Friends, Disney Princesses), Ninjago, City, Minifigures, and then IPs.

Then straight to fan Q&A:

-What’s the Asia strategy?

—China is LEGO’s fastest growing market and a discussion on the Monkey King line

-More on plant based pieces and the desire to expand their production

-What is the future of modular buildings with the new 18+ line?

—No plans now, but would like to have more modular type builds for families to build together

-Will LEGO continue to produce large numbers of new models?

—They are growing, but don’t want to go too fast/far

-What was his best LEGO moment?

—He mentioned the bringing bricks to children who had never seen them before and didn’t know what to do to them stories.

-What are some of the latest models?

—The Child, The Child Brickheadz, and a Ninjago model (I didn’t catch the name)

-Will shelf life decrease with more sets coming out?

—They would actually like to expand the shelf life

-Why re-release the two IDEAS sets (Ship in a Bottle and Saturn V)?

—It’s hard to predict product popularity and there was still demand even after the sets went to end of life

-What is the long term plan for LEGO apps?

—Need to determine how they will support them into the future

-A discussion on IPs

--Need to consider if kids like the IP, determine what LEGO can do with it, and if it fits within the brand

-A question about becoming a designer (been asked a lot so I won’t expand on the answer)

-A question on virtual designing (he wasn’t an expert there)

-How long does it take to design a set?

—Anywhere from 9 to 15 months to design a set

-How many people to design a set?

—It depends on the set, but there are around 400 designers and then 1,800 people who do marketing, packaging, and instruction development

-Why is LEGO successful?

—They’ve been able to make it a system and connect well with partners

-Any challenges with working form home?

—Designers have a hard time getting the pieces they need

-What are his favorite lines?

—Ninjago, Bionicle, and the new Nintendo line

-What are the long term plans for the Art line

—The Star Wars Sith set has done well. Expect more sets.

-Why are some sets phased out faster than others?

—They stick with what works. For example, Ninjago did better than Chima or Nexo Knights

-Could old sticker sheets be re-released?

—”That’s a good idea.”

-What is the design process?

—Talk to kids worldwide, get ideas, draw the ideas, show kids, build models, test with kids, do internal reviews

-How do you decide to do printed pieces versus stickers?

—Try to print more for younger kids and can get more authenticity with more stickers. They have more flexibility with fewer stickers.

-A discussion on LEGO animals

—Molded ones are meant for younger kids (Duplo) and brick built ones are for older kids and to expand creativity

-How many sets does each designer work on?

—Depends on the team and the product line. Ninjago team works on all sets, but they are the lead for one or two each year.

-Do they test sets with adults?

—Starting to test them with adults now. Small scale test. (how do I sign up for this?)

Next up was Stuart Harris who is the lead designer for the LEGO House®. He displayed some of the new fan designs they have on display in the Yellow Zone. I was too busy paying attention to the designs to take any screen shots. Sorry!

Okay… Next presentation was with Kim Yde Larsen, Nanna Mazanti Drejer Friborg and Thomas Folit. They are part of the BIX team or Building Instructions Experience team. Here are their minifig recreations from the slide show.

Their presentation was focused on the building instruction process starting with the history to where they are today. This isn’t an area we hear a lot about so it was interesting to hear their perspective. There is a lot to think about besides making sure you can make the set. Who will be making the set? Are they young/old, familiar with LEGO or not, is the set large or small? They discussed how they go through this all as a set is designed. Then we moved to the Q&A:

-When are they involved in the process?

—During the early stages of development all the way through pre-launch and then post launch if needed

-Please tell customer service if you find issues so they can fix them.

-What happens when errors are found in models?

—The goal is to find errors before the model is released which is why they get involved very early in the process.

-Would it be possible to add a number code for color blind people?

—This is definitely a possibility.

-They are aware of the concerns with the instruction issues with #10277-1 Crocodile Locomotive (dark pieces and a black background).

-Why is glossy papers used for instructions?

—It is readily available.

-What was the hardest set to make instructions for?

—It is not always complexity or a large adult set. Some of the sets designed for little kids can be harder because you have to make sure they can put it together

-The team has made changes post release of a set.

-How many people are on the instructions team?

—60

Here are the presenters for that section:

Kim

Nanna

Thomis

Next up Stephan Sander and Thomas Wesselski talked about Skaerbaek Fan Weekend and why it was cancelled.

Last presentation was Bjarke Schønwandt who is a quality director and works with Consumer-Perceived Quality at LEGO. I wasn’t sure what to expect on this one, but it was actually pretty interesting and I didn’t know LEGO did a lot of this stuff. I took a bunch of screen shots during this presentation so I’ll put a few up here. First, some info on Bjarke…

If I had to sum up what Bjarke does, the goal of him and his team is to make sure LEGO’s customers are happy. The product may meet LEGO’s standards, but if it doesn’t meet consumer standards, then it doesn’t work. Bjarke discussed how they measure consumer perceived quality. For example, they expect complaints to go up when sales increase and they expect more mistakes to happen with bigger sets.

He showed a chart with where LEGO sees its complaints. 86% come from missing pieces and 13% are faulty pieces. There rest in in a few smaller categories.

Missing pieces come from having the wrong element in the set, a customer losing the part, or missing minifigures. Bjarke noted that they see more Star Wars Storm Troopers and Ninjago figures going missing than City fire fighters. He made a quick quip that there is probably a reason for this.

Bjarke talked about systematic building mistakes. This is where people screw up the build and then have pieces “missing” later only to find out they followed the instructions wrong. I fully admit I have done this and so have you so just admit it.

Okay, I think we’re onto Q&A here…

-How often does LEGO make checks to parts during production?

—About once every 8 hours. It would be too hard to check every piece coming out of the factory.

-How often do they make changes to elements?

—Changes happen often. Some are for sustainability purposes.

-What can you say about the LEGO Technic Lamborghini issues (#42115-1)?

—I will do my best to summarize the discussion. It was pretty detailed and technical, but it made sense when he was done. There were a few issues.

—-One element was out of spec as the color pigments burned in the mold as it was in the mold too long. They haven’t fixed the issue, but they cheated by using a different machine to get the elements in spec.

—-The other issue is related to material suppliers. They have a specific tolerance that they need the colors to be in. Then the material team has a tolerance. The tolerances can be in different directions (for a green piece, more red, more blue, more yellow, etc.) and so the supplier and the materials team can both go in different directions while still meeting spec. However, LEGO found out this didn’t work on the Lamborghini with color differences between parts next to each other as Bjarke showed us.

Bjarke conveniently brought the Technic Lamborghini with him to the presentation

Bjarke explaining color tolerances

-What about the brown elements breaking?

—LEGO was aware of them too. They are working on fixing issues with suppliers and getting colors into the same quadrant of the color scale.

-A few examples of systematic building mistakes:

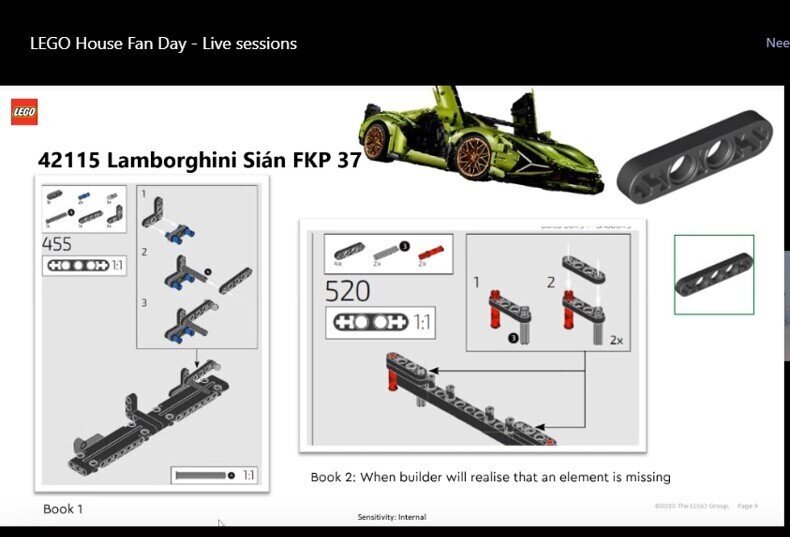

#1 - LEGO found a lot of people selecting the wrong piece at step #455 on the Technic Lamborghini (#42115-1). Then when they needed that piece at set #520, they didn’t have the correct piece. No one wants to disassemble at that point.

#2 - #75551-1: Minion has an error that many people make (including Bjarke) at step 21 and then find out they messed it up at step 79.

-What is perceived quality?

—If fans think it isn’t good, then it isn’t good.

-What other errors have you seen?

—The Ford Mustang (#10265-1) has a racing stripe that isn’t as straight as some fans want it to be.

-Why did you change the materials in the transparent bricks?

—To have more sustainable parts

-How do you get your white elements to stay white?

—Keep them out of the sun (he wasn’t sure what else to do).

-Why do some stickers crack after a while and some done?

—They don’t know.

-What are the hardest parts to make?

—The dark earth colors

-Why not just use one supplier so the colors are the same?

—Don’t want to use one supplier and then run supply chain risks if that supplier is disrupted

-How long did the Wall-E (#21303-1) fix take?

—1-2 weeks to rebuild, 1-2 weeks for instructions, production time, and then time to get it into the supply chain. It didn’t make sense to shut off a production run to do this fix and then re-start what was turned off.

-Please report issues to customer service. (I’m seeing a trend)

-Why don’t the instruction colors match the bricks you are using?

—They need to adjust the colors to make sure they can get the 3-D effect on the instructions.

-What are your biggest issues right now?

—#42115-1: Lamborghini Sian and parts sustainability

Whew! That was a lot. Some great information and very interesting. Definitely different from having designers talk which is what I’m used to seeing. I hope LEGO continues events like these and I hope my summary of the event was worthwhile for you to read if you couldn’t make the event.

Bye from Billund!